Product Categories

- Ultra-high molecular polyethylene sheet

- High density polyethylene sheet

- Coal bunker liner car skateboard

- Ultra-polymer plastic bearing

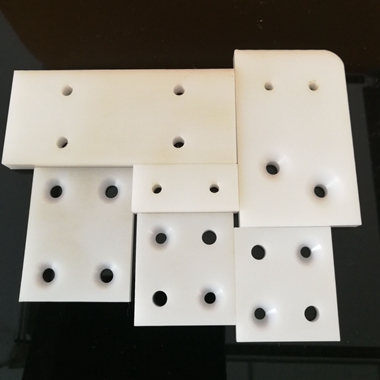

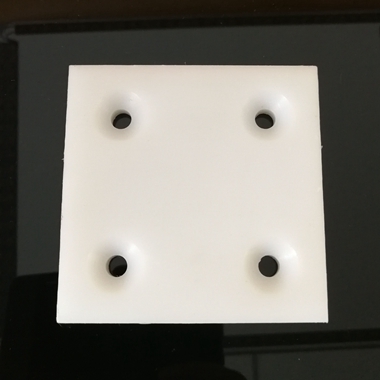

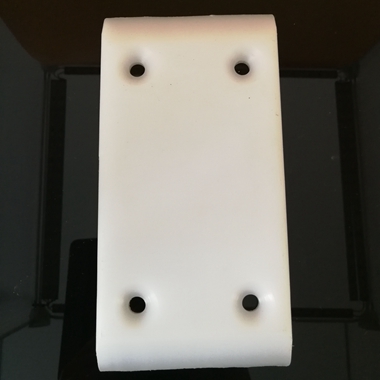

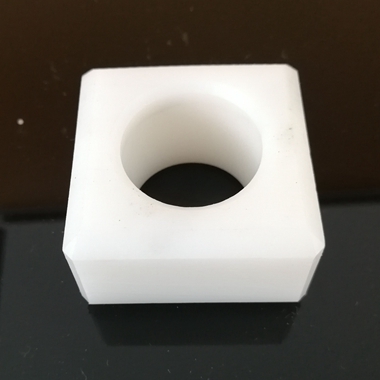

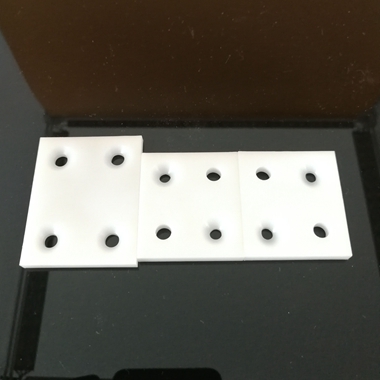

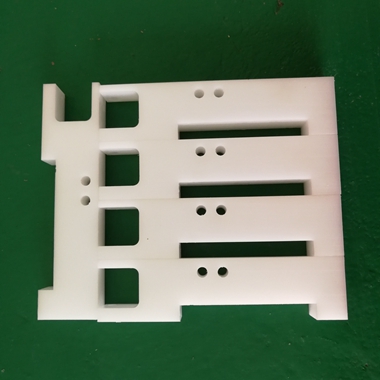

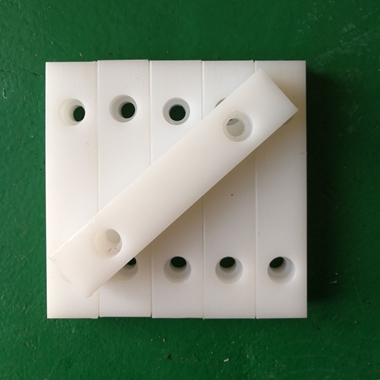

- Ultra-high molecular polyethylene shaped parts

- Nylon product processing customization

- Nylon products shaped parts processing

- Customized processing of plastic products such as POM and ABS

Contact us

Sales one:15297688181

E-mail:1125044001@qq.com

Sales two:15297688282

E-mail:Jack@hbmingze.com

Telephone:+86 318 5830699

Fax:+86 318 5830677

Address:Jingxian Development Zone, Hengshui City, Hebei Province, China

Plastic products are the collective name for life, industry and other products that are processed from plastic as the main raw material. Including plastics as raw materials for injection molding, plastic molding and other processes of products. Plastic is a kind of synthetic polymer material with plasticity.

It forms three major synthetic materials that are indispensable for daily life with synthetic rubber and synthetic fibers. Specifically, the plastic is a material which is made of a natural or synthetic resin as a main component, is added with various additives, can be molded into a certain shape under a certain temperature and pressure, and maintains a shape at a normal temperature.

Compared with other materials, plastic has the following performance characteristics:

1. Light weight

Plastics are lighter materials with a relative density between 0.90 and 2.2. Obviously, can plastics float to the surface? In particular, foamed plastics have a lighter texture and a lighter density with a relative density of only 0.01. This property allows plastics to be used in the production of products that require a reduction in their own weight.

2. Excellent chemical stability

Most plastics have good corrosion resistance to acids, alkalis and other chemicals. Especially known as the plastic king of PTFE (F4), its chemical stability is even better than gold, put in "Aqua regia" boiled for more than ten hours will not deteriorate. Due to its excellent chemical stability, F4 is an ideal corrosion resistant material. For example, F4 can be used as a material for conveying corrosive and viscous liquid pipes.

3. Excellent electrical insulation properties

Ordinary plastics are poor conductors of electricity, and their surface resistance and volume resistance are very large, which can be represented by numbers to 109 to 1018 ohms. The breakdown voltage is large and the dielectric loss tangent is small. Therefore, plastics have a wide range of applications in the electronics and machinery industries. Such as plastic insulated control cables.

4. Poor conductor of heat, with noise reduction and shock absorption

In general, the thermal conductivity of plastics is relatively low, equivalent to 1/75 to 1/25 of steel, the micropores of foam.

It contains gas, which is better in heat insulation, sound insulation and shock resistance. For example, the thermal conductivity of polyvinyl chloride (PVC) is only 1/357 of that of steel and 1/1250 of aluminum. In terms of heat insulation capacity, the single glass plastic window is 40% higher than the single glass aluminum window, and the double glass is 50% higher. After combining the plastic form with the insulating glass, it is used in residential buildings, office buildings, wards, hotels, saving heating in winter and saving air conditioning costs in summer. The benefits are obvious.

5. Wide mechanical strength distribution and high specific strength

Some plastics are as hard as stones, steel, and some are soft like paper and leather. From the mechanical properties of hardness, tensile strength, elongation and impact strength of plastics, the distribution range is wide, and there is a great choice for use. Because of its small specific gravity and high strength, plastics have a high specific strength. Compared with other materials, plastics also have obvious disadvantages, such as easy burning, low rigidity, poor aging resistance, and heat resistance.