Product Categories

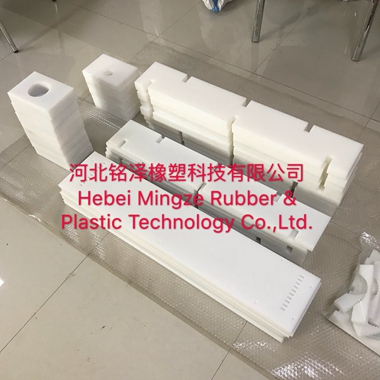

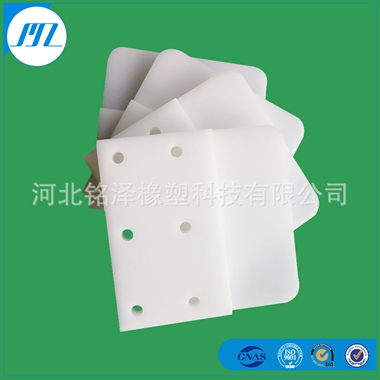

- Ultra-high molecular polyethylene sheet

- High density polyethylene sheet

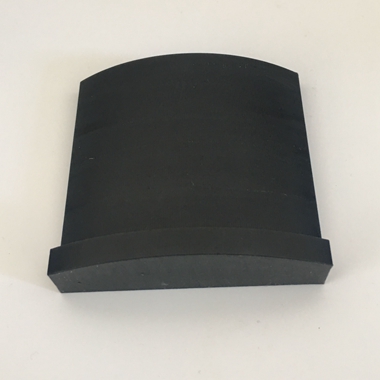

- Coal bunker liner car skateboard

- Ultra-polymer plastic bearing

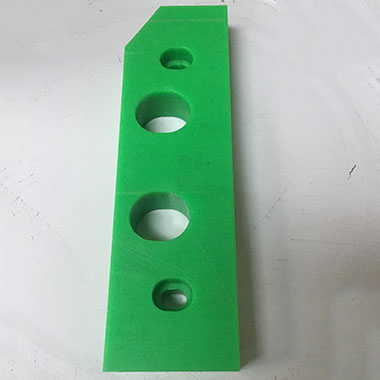

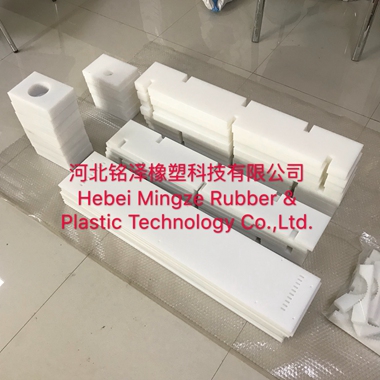

- Ultra-high molecular polyethylene shaped parts

- Nylon product processing customization

- Nylon products shaped parts processing

- Customized processing of plastic products such as POM and ABS

Contact us

Sales one:15297688181

E-mail:1125044001@qq.com

Sales two:15297688282

E-mail:Jack@hbmingze.com

Telephone:+86 318 5830699

Fax:+86 318 5830677

Address:Jingxian Development Zone, Hengshui City, Hebei Province, China

The ultra high molecular weight polyethylene English name is UHMWPE, which is a polyethylene with a molecular weight of 1.5 million or more. The heat distortion temperature (0.46 MPa) is 85 ° C, and the melting point is 130 to 136 ° C.

The characteristics of UHMWPE are: excellent wear resistance, good low temperature impact resistance, self-lubricating, non-toxic, water and chemical resistance, and heat resistance is better than general PE. It is called "amazing material" by Europe and America.

Special features:

The mechanical properties are higher than the general high density polyethylene. It has outstanding impact resistance, stress crack resistance, high temperature creep resistance, low friction coefficient, self-lubricating property, excellent chemical resistance, fatigue resistance, noise damping, and nuclear radiation resistance.

Use temperature: -100 ~ 110 °C. Good cold resistance, can be used at -269 °C. The product with a molecular weight of 2 million has a tensile strength at break of 40 MPa, an elongation at break of 350%, a flexural modulus of elasticity of 600 MPa, and a notched impact of the cantilever beam. The amount of wear (MPC method) is 20 mm.

Application:

Because UHMWPE has excellent physical and mechanical properties and non-toxic, odorless, non-absorbent, non-adhesive, corrosion-resistant, light-weight and many other advantages, it has a great application market in the packaging and food machinery industry. Rollers, chain links, chains, worms, guides, gears, star wheels, handwheels, rollers, screw rods of various shapes and structures have been successfully supplied to various packaging and food machinery and filling lines. Accessories for guard rails, hoppers, filter plates, operating panels, scrapers, grippers, linings, plungers, etc.

In the food industry, ultra-high molecular weight polyethylene is used in the conveying pipeline of canned and bottled foods, which not only enables smooth transportation, but also prevents collision of bottles and greatly reduces noise. Ultra-high molecular weight polyethylene is used in the packaging lines of confectionery products such as powdered foods, instant foods and chocolates. Its sliding properties and durability are widely appreciated.